Hydraulic Power Packs

Previous

Next

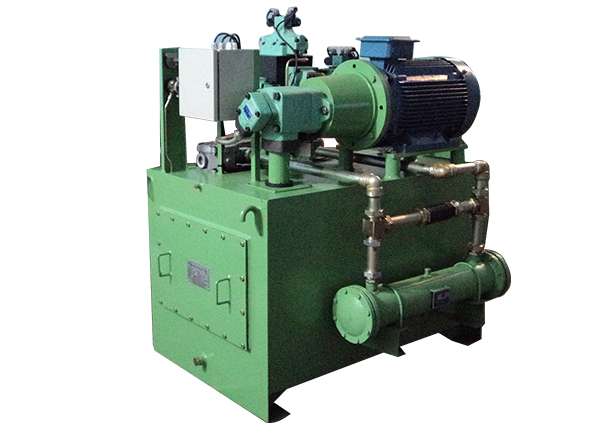

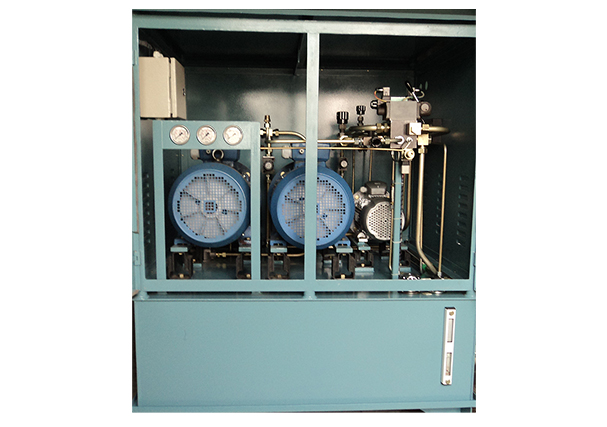

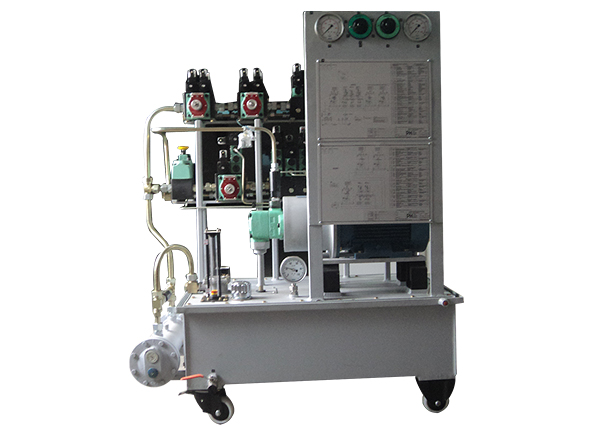

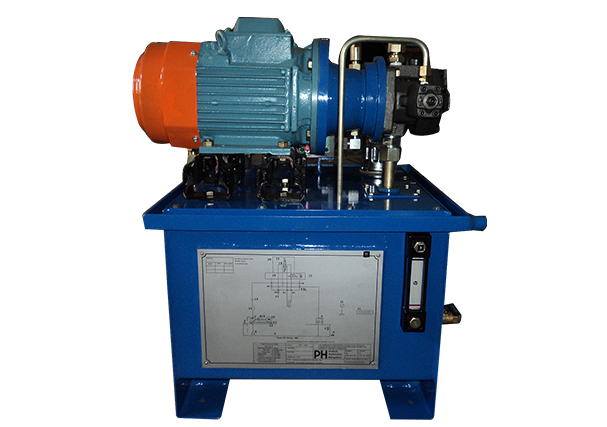

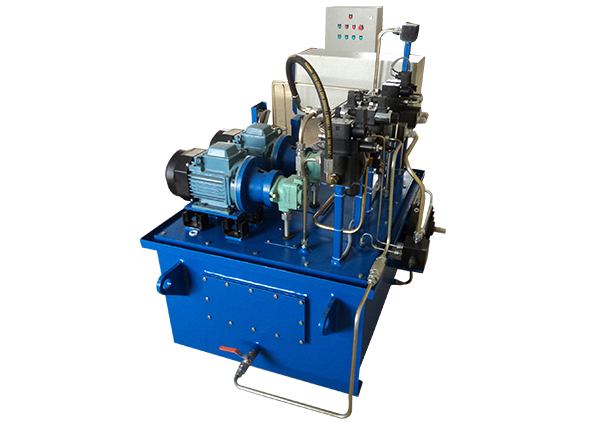

Hydraulic Power Packs

Hydrodex supplies a wide range of customized hydraulic power packs for industial, marina and mobile application. Our product range include standard power packs, as well as specialized and compact power packs.

Guidelines for design, development, manufacturing, assembly and testing of hydraulic cylinders.

Design of power packs based on

- Area of application like industrial, marine, mobile etc.

- Forces and speed developed at actuators.

- Position, speed and force control requirements (open and closed loop).

- Expected working cycles.

- Ambient conditions.

Standards

The power packs manufactured by us are in accordance with ISO 5598:2019 and ISO 4413:2010.

Types

- Standard power packs: material handling equipment, scissor lifts, dock leveler etc.

- Special power packs: machine tool applications, CNC turning and milling, hydraulic presses, cranes, boat davits, loading arms, windmills, testing benches, press brake systems, punching presses (up to 1000 hits/min), sintering presses, rubber and plywood presses etc.

- Power packs running on water glycol solution.

Specifications

- Tank size: up to 3000 liters.

- Prime mover: up to 300HP.

- Pressure: up to 700 bar.

- Medium: Mineral oil, water glycol solution, ATF etc.

- Accumulator backup: 50 liters x 10 units.

- Working temperature: up to 90° Celsius.

- Positional accuracy: up to 10 µm.

- ATEX certified valves.

Additional features

- CE certification.

- Electrical panels certified to UL/CE/ATEX safety standards.

- Zinc trivalent coating or painting.

- CAD/STEP/IGES models of every power pack.

Testing standards

- Hydraulic systems: ISO 4413:2010

- Hose assemblies: ISO 6605:2017

- Pipelines: EN 10216

Cleaning standards

As per ISO 4406. The power packs are assembled in a clean-room environment.